Recovering Heat from Waste Water

Sanitary water heating plays a big part in the energy consumption of buildings. Recovering a part of this energy normally dispersed through water drains is an important saving, both for the end user and for the entire community. Recent European regulations and directives (RES) on renewable energies are progressively increasing the obligation to use renewable energies.

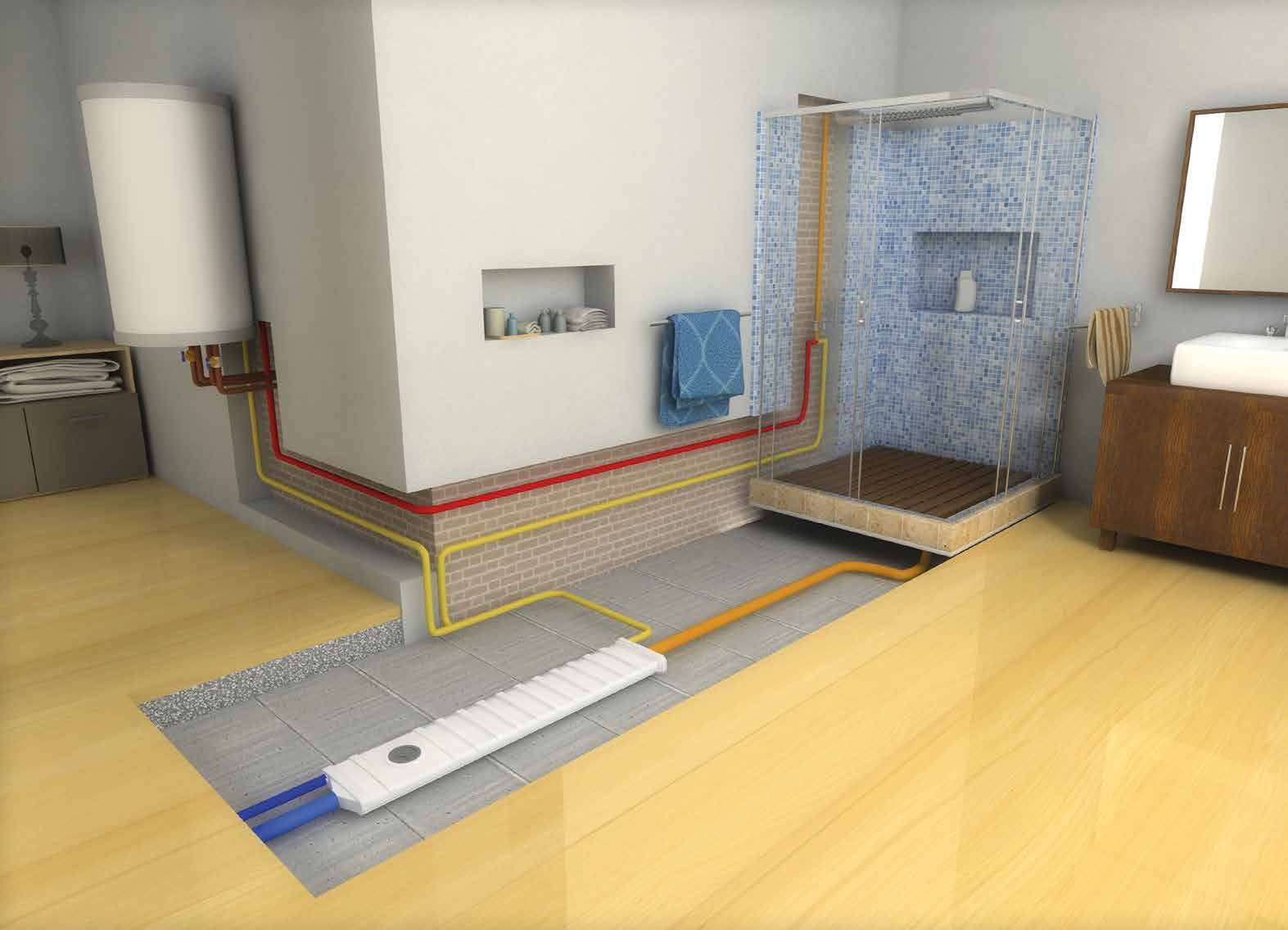

Heat recovery from wastewater is a revolutionary device that will effectively change the way domestic pipings are designed. Exchanging the heat between waste water and water feed from the mains recovers a significant amount of heat that would otherwise be dispersed into the environment.

How it Works

A waste water heat recovery system works by extracting heat from waste water (e.g. from your bath, shower, washing machine) going down the drain. This heat is re-used to warm mains water on it's way to the boiler, reducing the amount of energy required to heat the water up to the required temperature.

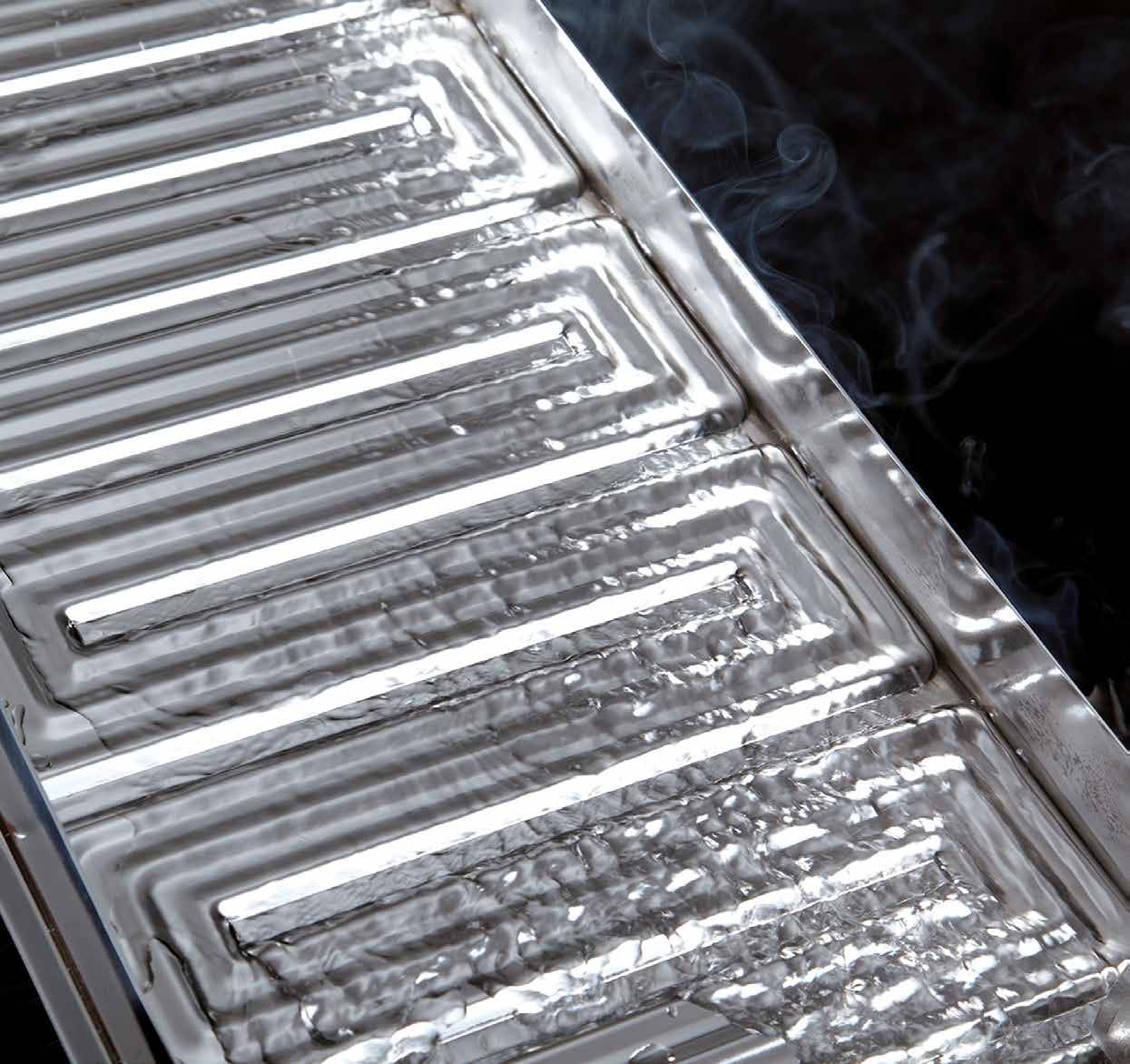

Waste water passes above two specially shaped corrosion-resistant metal sheets. Clean water is preheated by heat from the drainage water before flowing to the boiler. Because of this, the boiler is fed by water at a higher temperature, thus reducing the energy required to heat this water.

The reliability and durability of this device is the same as a common drain pipe, and does not interfere with existing systems or accumulate any dirt. Maintenance of the system is extremely simple and easy, as with standard pipes for waste water drainage. The achievable heat recovery goes from 30% to 75% depending on the length installed (it is possible to use more exchangers in series or parallel) and water flow.

Is it worth retrofitting a WWHRS?

The majority of systems available today require fitting a large and bulky recovery device, making it difficult to adapt existing systems. However, Elite Climate Control's Bee system has a slim profile which is suitable for retrofitting to most systems.

The cost, of both purchase and installation, allows a quick return on investment (5-10 months for intensive hot water use, to a maximum of 2-3 years for normal use).

Techical Details

| Exchanger material | AISI 316 L Stainless steel sheet material |

| Domestic hot water fittings | AISI 304 Stainless steel sheet |

| Casing material | Polypropylene (PP) |

| Material sealing rings | EPDM |

| Maximum temperature of continuous operation | 80°C |

| Maximum temperature of intermittent flow | 100°C |

| Maximum operating pressure exchanger (DHW) | 10 BAR |

| Maximum operating pressure duct (drain) | 0.5 BAR |

| Domestic hot water | 1/2" |

| Drain connections | 50mm |

| Weight | BEE® 600 - 5.3kg BEE® 1300 - 10.1kg |